Kral Screw Pumps

Kral Screw Pumps

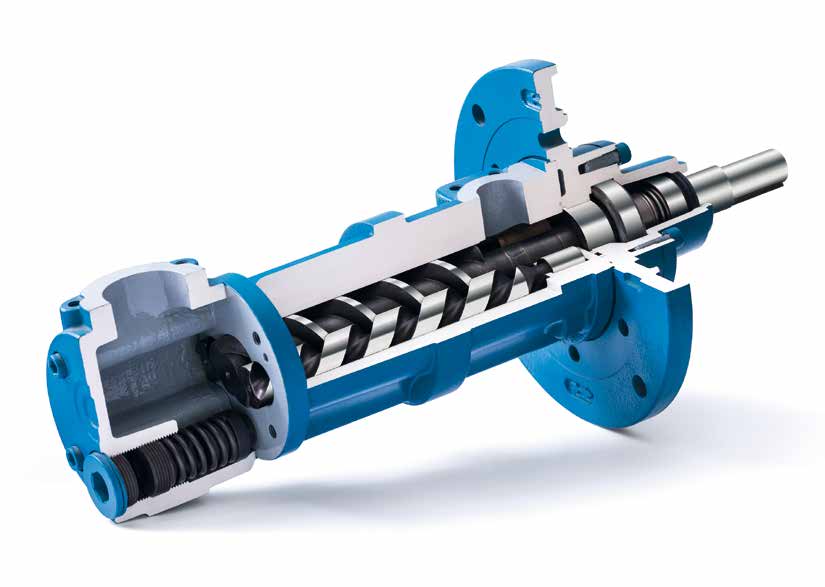

KRAL three screw pumps have clear technical advantages.

Pumping liquids is a demanding task. When selecting and dimensioning a three screw pump, the pumped liquid, the operating conditions, the installation site as well as the standards, guidelines and directives have to be taken into consideration. A wealth of knowledge is required in order to avoid errors.

KRAL three screw pumps have existed since 1950. The acquired experience is passed on from generation to generation and extended continuously. Thus ensuring employees with excellent knowledge and further training. Our customers profit from our advisory skills.

Space for setting up or installing three screw pumps is expensive or often short. KRAL three screw pumps offer high delivery rates at small space requirements in comparison to other pump types.

The delivery rate of a three screw pump depends strongly on the speed. If the delivery rate has to be varied, a controller has to change the rotational speed. The complexity of the controller design depends on the delivery rate characteristics of the screw pump. In contrast to many other functional principles, KRAL three screw pumpshave linear delivery rate characteristics. Therefore they can be controlled simply and inexpensively by means of a frequency converter.

Pressure pulsations of the liquid can damage the three screw pump, the system and the pumped liquid. The strength of the pulsation depends on the functional principle of the pump. Piston and gear pumps cause considerably more pulsations than a three screw pump. KRAL three screw pumps feed product-conservingly. The pumped liquid is not pressed, there are no pressure pulses that can damage the piping and other components or trigger vibrations. In addition, KRAL three screw pumps are very quiet.